Dozamet is one of the few producers of tubing segments in the world. We produce tubings to be used for the construction of

- mineshafts in potassium, copper, coal mines, etc.

- ventilation shafts

- underground subway tunnels

- other tunnel structures to secure and protest passages in difficult mining and geological conditions

Advantages of using cast iron tubings:

- high load strength

- waterproofness

- the lowest costs in specific geological conditions

- the longest durability

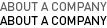

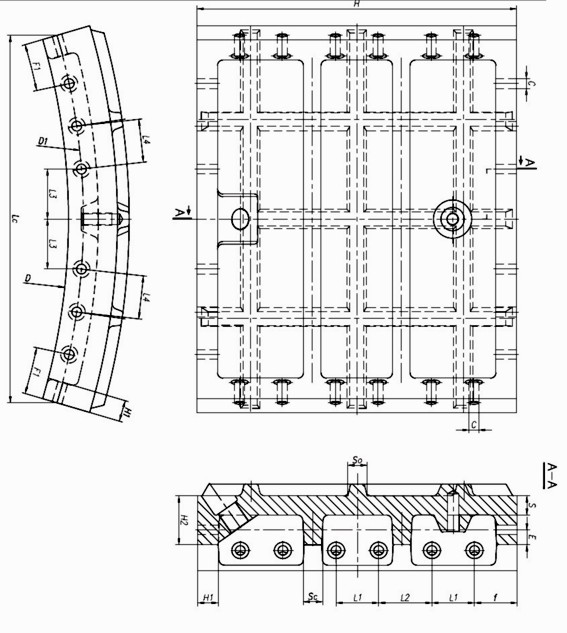

Tubings are made of ductile (or grey) iron. A typical tubing is a shaft sector which bolted with successive tubings makes a ring functioning as a housing. According to another definition tubings are cast and anti-corrosion protected segments of shaft rings produced according to DIN 21501.

The segments are assembled on site into hollow rings joined by bolts and compressed by means of special concrete. Housings made of tubings are used as sealing in difficult mining and geological conditions: in high rock pressure, quicksand conditions, etc. They provide high safety. Cast iron tubings are used to make mineshaft walls, some underground subway tunnels, ventilation shafts, etc.

Definitions:

Tubbing - Shaft lining segment of cylindrical nature made of ductile cast iron

Tubbing ring - A lining ring composed of tubbing segments bolted to one another by bolts

Inner Surface of Tubbing Wall - Tubbing surface area from the inner side of the shaft

Outer Surface of Tubbing Wall - Tubbing surface area from the outer side of the shaft

Outer Ribs - A rib located on the outer side of the tubbing wall.

Inner Ribs - A rib located on the inner side of the tubbing wall

Vertical Flange - Vertical flange in which holes are drilled to allow tubbing segments to be bolted to one another.

Horizontal Flange - Horizontal flange in which holes are drilled to allow tubbing rings to be bolted to one another.

Table 1. Critical dimensional tolerances of segments

| ITEM DESCRIPTION | DENOMINATION |

| Inner ring radius | D |

| Effectivwe diameter of holes f46 | D1 |

| Segment height | H |

| Segment length (chord) | Lc – dla średnicy f6140 |

| Bolt hole circle diameter | C |

| Bolt hole sparing | L1, L2, L3, L4 |

| Distance of bolt hole circle from inside of flange | E |

| Difference between segment heights in ring | Hmax.- Hmin |

| Thickness of flange | H1 |

| Height of flange | H2 |

| Thickness of internal/external rib | So, Sc |

| Average tubbing wall thickness variation from nominal thickness, measured in five points | S |

| Distance of first hole's axle from segment edge | f,F1 |

Sample of our references:

- PCS – Potash Corporation Saskatchewan, Canada – 468 tubbing segments made from ductile cast iron GGG50. Contract was finished in 1999.

- PeBeKa – Lubin, Poland, - since 1962 to 1996 – 6500 pcs. of tubbing segments.

- PROMSI, Moscow, Russia.

- Przedsiębiorstwo Budowy Szybów Bytom, Poland.

- Kopalnia węgla kamiennego Bogdanka, (Coalmine Bogdanka), Puchaczów, Poland.

- PCS – Potash Corporation Saskatchewan, Canada – 1254 tubbing segments made from ductile cast iron GGG50